Ultrasonic Cleaning for Automotive Servicing & Reconditioning

Automotive repair, manufacturing and rebuilding companies turn to ultrasonic cleaning technology to remove dirt and contamination from various parts and components.

Eliminate Automotive Contaminants

Automotive repair, manufacturing and rebuilding companies turn to ultrasonic cleaning technology to remove dirt and contamination from various parts and components. Kleentek solutions eliminate automotive contaminants such as oil, grease, metal shavings, lubricants, rust, and carcinogens from automotive parts for consistently clean components. Our MetalKleen range is specifically designed for automotive workshops.

Our ultrasonic range for the automotive industry:

-

MetalKleen 50L Ultrasonic Cleaner

MetalKleen 50L Ultrasonic Cleaner -

MetalKleen 150L

MetalKleen 150L -

MiSonics MSX500 Industrial Ultrasonic Cleaner

MiSonics MSX500 Industrial Ultrasonic Cleaner -

MSX50 Ultrasonic Cleaner

MSX50 Ultrasonic Cleaner -

MSX70 Ultrasonic Cleaner

MSX70 Ultrasonic Cleaner -

MSX240 Industrial Ultrasonic Cleaner

MSX240 Industrial Ultrasonic Cleaner -

MSX140 Industrial Ultrasonic Cleaner

MSX140 Industrial Ultrasonic Cleaner -

Brulin AquaVantage 815QR-NF$121.00 – $429.00

Brulin AquaVantage 815QR-NF$121.00 – $429.00 -

MiSonics MSX30 MF Benchtop Ultrasonic Cleaner$6,369.00

MiSonics MSX30 MF Benchtop Ultrasonic Cleaner$6,369.00

Customer Testimonials

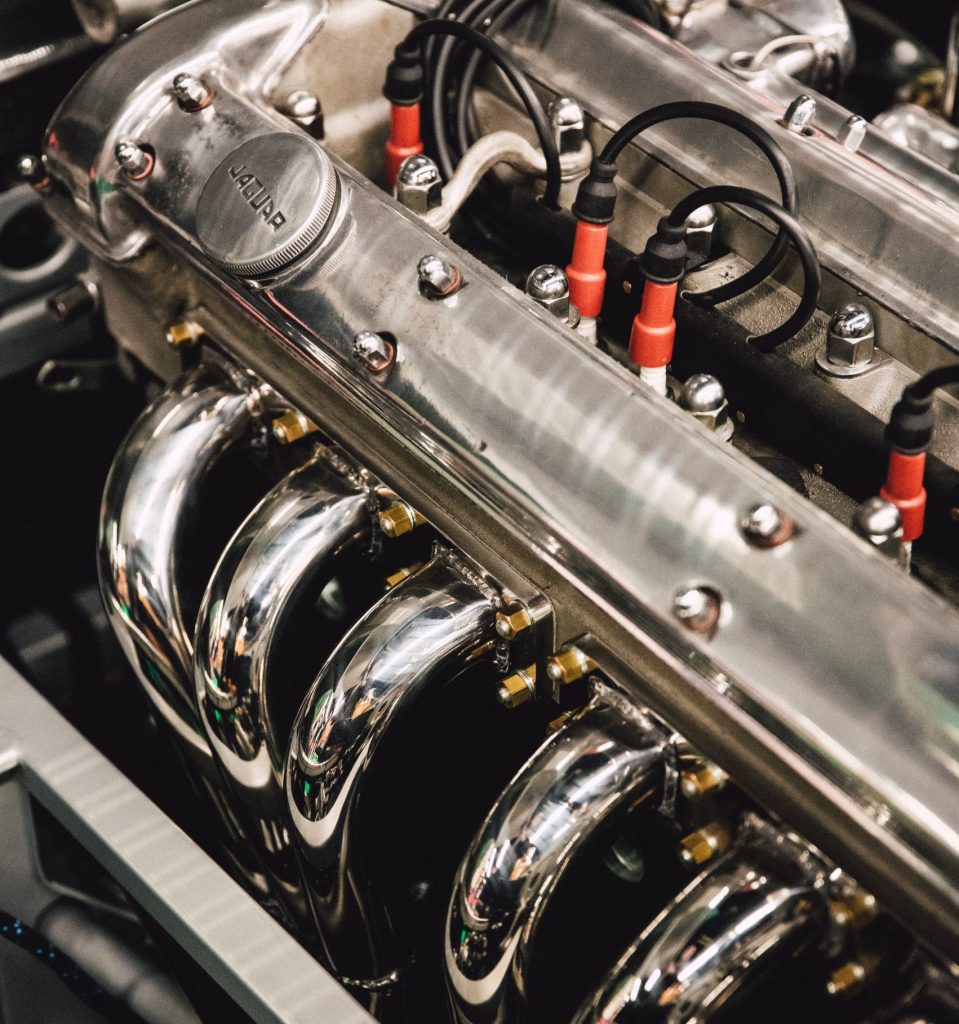

Engine Reconditioning with Ultrasonics

Engine reconditioners and automatic transmission companies turn to Kleentek for ultrasonic cleaning that is fast, efficient, affordable and environmentally friendly. This method has been proven successful in cleaning alloy heads to reduce bead blasting by up to 95% while providing substantial cost savings. The reduction of bead blasting also dramatically reduces the potential for further damage to the head once fitted. Our range of industrial ultrasonic cleaning tanks improves productivity in the automotive workshop by automating cleaning of components such as inlet (air intake) manifolds, engine heads, carburettors and even entire engine blocks.

Automatic Transmissions

Automatic transmission companies have had major success in cleaning valve bodies and various gear box components using ultrasonic technology. Cleaning times are reduced, cleaning effectiveness is improved and there is no longer a use for cacogenic solvents when ultrasonic technology is used—this reduces the carbon footprint that automotive companies place on the environment in an effort to properly clean parts and components.

Vehicle Radiators

Kleentek has developed an ultrasonic cleaner that is specially designed to clean the internal and external parts of vehicle radiators, industrial compressors and hydraulic coolers of all shapes and sizes. Utilising unique cleaning techniques that incorporate a large high powered cleaning tank with a weir system, pump and filtration systems, this ultrasonic cleaning can bring nearly any clogged up radiator back to life by eliminating build up that limit proper function.

Watch: How the Holden Racing Team use Ultrasonic Cleaning

- Restore blocked coolers

- Extend the life of a cooler

- Clean inaccessible places

- Promote thorough flushing

- Release baked on metals

Cleaning Brake & Steering Assemblies

All aspects of brake assemblies; drums, housings, brake lines and pistons can be clean effectively in ultrasonics using the correct chemistry. Where a number of different components are made from different materials Kleentek has designed machines that can run different ultrasonics cleaning solutions to suit the requirement in the same ultrasonic machine resulting in substantial cost savings.

All the steering assemblies, once it has been disassembled and gross cleaned can be critically cleaned in ultrasonics. Hard to get at crevices and assemblies will be cleaned very effectively.

Diesel Servicing with Ultrasonics

In this fast changing field of diesel injection and pump servicing, the combination of ultrasonics and new ultrasonics cleaning solutions has resulted in reducing the use of bead blasting significantly. When cleanliness is of the utmost importance you cannot go past ultrasonics to achieve that final critical clean before going to the clean room for assembly. Ultrasonics can also remove paint from external surfaces of pump assemblies as well. Why risk bead or sodium bicarbonate residue in a pump assembly when ultrasonics can take the worry away. It is the only safe effective way to clean.