Using Ultrasonics in Engineering & Manufacturing

Ultrasonic Technology: The Ultimate Precision Cleaning Solution

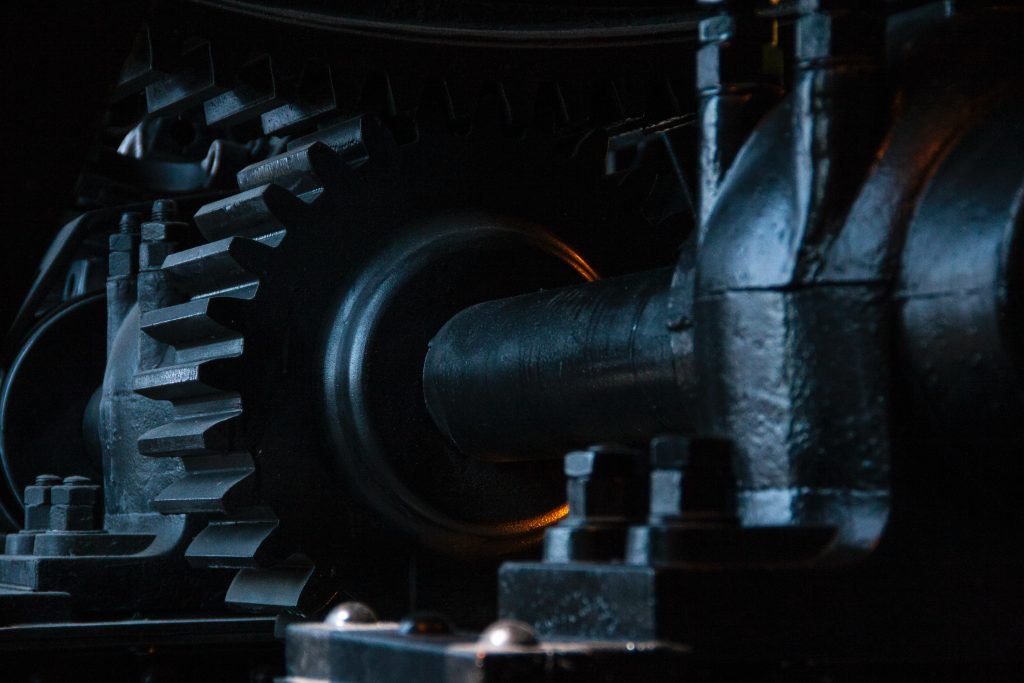

In the engineering industry, ultrasonic technology helps manufacturers to meet precision cleaning requirements by addressing every cleaning and parts washing application fathomable. Machine oils and grease are often left behind during the manufacturing process; these residues must be cleaned to provide adequate bonding to the substrate for additional processes such as electroplating, polishing or powder coating following the manufacturing of the product. Ultrasonic cleaning is the solution.

Certain products, such as prosthetic limbs that are used in the medical industry, or precision parts used in the motor racing and automotive industry must be thoroughly cleaned for both aesthetic purposes and simply due to the sensitive nature of the component.

Our ultrasonic range for Engineering:

-

TM-250 Mega Tank

TM-250 Mega Tank -

TM-800 Mega Tank

TM-800 Mega Tank -

MiSonics MSX500 Industrial Ultrasonic Cleaner

MiSonics MSX500 Industrial Ultrasonic Cleaner -

MSX50 Ultrasonic Cleaner

MSX50 Ultrasonic Cleaner -

MSX70 Ultrasonic Cleaner

MSX70 Ultrasonic Cleaner -

MSX240 Industrial Ultrasonic Cleaner

MSX240 Industrial Ultrasonic Cleaner -

MSX140 Industrial Ultrasonic Cleaner

MSX140 Industrial Ultrasonic Cleaner -

Brulin MP 1793 Multi-Purpose Wipe Solvent$38.50 – $363.00

Brulin MP 1793 Multi-Purpose Wipe Solvent$38.50 – $363.00 -

Brulin AquaVantage 815QR-NF$121.00 – $429.00

Brulin AquaVantage 815QR-NF$121.00 – $429.00

Customer Testimonials

Ultrasonics, in conjunction with corrective chemistry for each application, provides an effective and efficient application to deliver desired cleanliness following manufacturing.

A multi-stage workstation is commonly used in the engineering industry to deliver cost effective cleaning solutions after the manufacturing process. This system includes a series of ultrasonic baths, passivation baths and rinse tanks that work to remove oils and compounds that are left behind during the cutting and machining process, to remove buffing and polishing compounds, and to remove rust, paint and finger prints from engineered parts.

Ultrasonic cleaning is ideal for:

- Turbo chargers

- Engine reconditioning (heads, pistons, cam rods, cam shafts, valves, valve springs, blocks, hydraulic pumps, rams, power takeoffs, drills)

- Diesel pumps

- Diesel injectors

- Brake calipers and cylinders

- Steering racks

- Carburetor cleaning