Ultrasonic Cleaning: A Guide

Ultrasonic cleaning has revolutionised the removal of contaminants from various surfaces across many industries. From delicate jewellery to industrial components, ultrasonic cleaning offers a versatile and efficient solution in a variety of applications.

How Does an Ultrasonic Cleaning Machine Work?

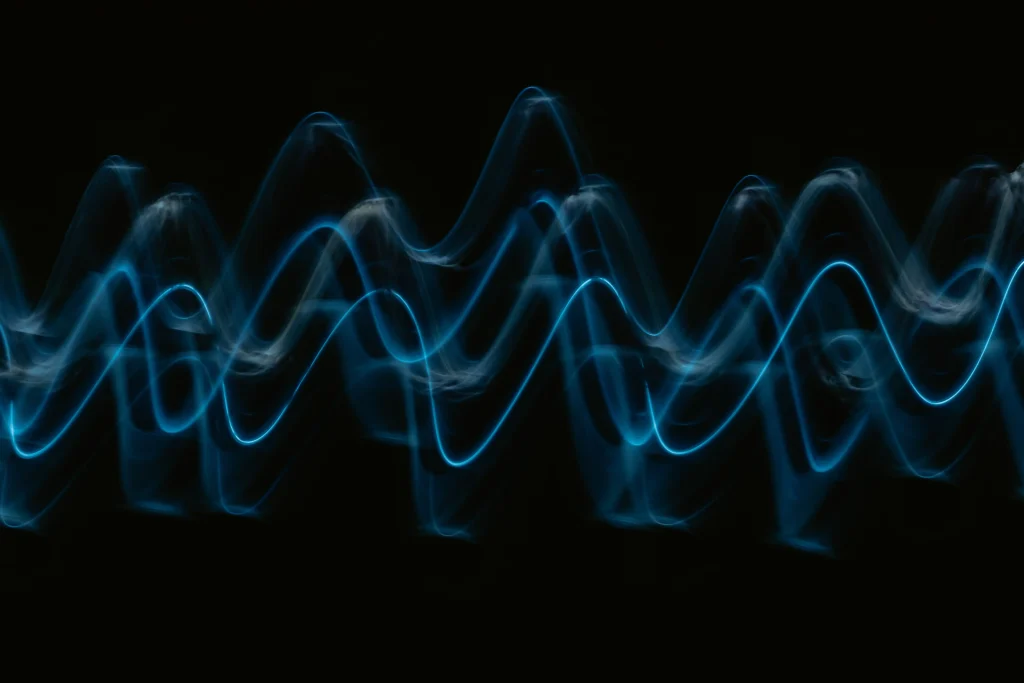

An ultrasonic cleaning machine utilises high-frequency sound waves, typically ranging from 20 to 40 kHz, to generate intense vibrations within a specialised tank known as an ultrasonic bath. These vibrations are created by transducers, which convert electrical energy into mechanical vibrations.

The ultrasonic bath or tank, filled with a suitable cleaning solution, facilitates the cleaning process.

It’s All About the Cavitation

Ultrasonic cleaning is driven by the force of cavitation, which occurs when bubbles form in liquid flow as the local pressure drops. These bubbles, created by sound waves passing through water, are not only powerful but also microscopic in size.

Unlike the bubbles that you see produced by a propeller, the bubbles in ultrasonic cleaning systems collapse almost instantly after formation.

This rapid collapse releases vacuum energy in the form of heat and pressure, generating an intense combination that fuels the remarkable cleaning capability and effectiveness of ultrasonic cleaning. By harnessing this power, ultrasonic cleaning systems deliver thorough and efficient cleaning results across various industries.

The Process of Ultrasonic Cleaning

During ultrasonic cleaning, the intense vibrations produced by the ultrasonic cleaning machine cause cavitation, resulting in the formation and implosion of countless microscopic bubbles in the cleaning solution. This phenomenon generates high-pressure jets and localised turbulence, effectively dislodging contaminants from the surface of objects being cleaned.

Several other factors influence the efficiency of the process:

- The shape of the component being cleaned may require agitation or rotation to remove trapped air and expose all areas to the ultrasonic cavitation process.

- Higher frequencies provide gentler and more penetrating cleaning, while lower frequencies are more aggressive and suitable for less sensitive substrates.

- Prior degassing removes trapped air within the liquid medium, allowing for better ultrasonic energy absorption and degradation of contaminants.

- Higher solution temperatures, typically around 45°C, enhance the cleaning chemistry’s effectiveness and accelerate the cleaning process.

- The power of the ultrasonic system, measured in Watts per Litre, is crucial for industrial cleaning. A power level exceeding 20 Watts per Litre ensures effective cleaning, even for larger tank volumes.

What Makes Ultrasonic Cleaning Different?

Ultrasonic cleaning offers distinct characteristics that make it a preferred choice for many applications:

- The intense agitation and cavitation ensure the removal of stubborn contaminants, including dirt, grease, and particles. This thorough cleaning ability makes ultrasonic cleaning highly effective for intricate objects with complex geometries and hard-to-reach areas.

- Ultrasonic cleaning is versatile across industries. From jewellery and scientific equipment to industrial components, it enables efficient cleaning of a wide range of objects and materials.

- Ultrasonic cleaning solutions optimise the cavitation process, and facilitate the removal of various contaminants: they play a crucial role in the clearing process. Selection is based on both the contaminant and the material being cleaned.

- In industrial settings, where large-scale cleaning is required, industrial ultrasonic cleaners provide robust and efficient solutions. These powerful machines are designed to handle heavy-duty cleaning tasks, with larger ultrasonic baths and the capability of accommodating larger objects or batches of items.

- Ultrasonic cleaning harnesses the power of sound waves to achieve thorough and precise cleaning results without the need for harsh chemicals or excessive water usage.

Ultrasonic cleaning machine technology plays a vital role in industries ranging from scientific laboratories to heavy-duty industrial cleaning tasks.

Embracing the power of ultrasonic cleaning enables effective and environmentally friendly cleaning, making it a preferred choice for maintaining the highest standards of cleanliness and hygiene.