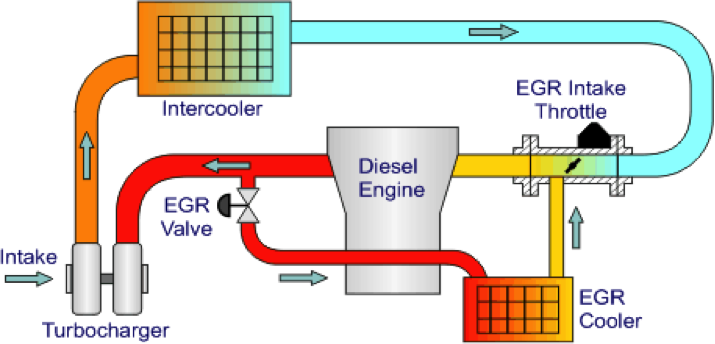

The Exhaust Gas Recirculation (EGR) valve is an anti-pollution device, aimed primarily at reducing the amount of nitrogen oxide (NOx) spewing out of the vehicle’s exhaust pipe. The engine produces nitrogen as part of the combustion process. As the temperatures inside the engine increase, this nitrogen and the oxygen in the engine’s combustion chamber can chemically combine to form nitrogen oxides.

NOx reacts with sunlight to cause smog. Exhaust Gas Recirculation works by recirculating a controlled portion of an engine’s exhaust fumes back through the engine. The EGR valve is the tap that turns the flow of exhaust gases on and off, hopefully at appropriate times.

These recycled, carbon dioxide-rich exhaust fumes cool the combustion chambers within the engine. This cooling effect lowers the combustion chamber temperature. The process also displaces some of the oxygen that would otherwise be drawn into the engine from the surrounding atmosphere. Because the combustion chamber is cooler and because there’s less oxygen, less NOx is produced. Also, because the combustion chambers are cooler, the engine as a whole runs cooler. This is particularly important to the engine’s turbocharger – turbochargers (and the oil that they need for their lubrication) don’t last long if the engine is overheating.

Because the EGR’s recycled exhaust gas displaces some of the air within the combustion chamber, the engine’s efficiency is reduced. For this reason, the EGR system doesn’t operate during times of heavy acceleration. It also doesn’t operate during idle, because the presence of exhaust gases at idle tends to cause uncontrollable rough running. EGR systems operate primarily when the vehicle is cruising under light load. Because there is less demand on the engine when the vehicle is cruising under light load, the engine can afford to temporarily lose some capacity.

Also, because of the cooling effect of the EGR system, the engine can run cooler when the vehicle is cruising under light load. Because the engine is cooler, the engine’s lubricating oil is cooler as well. Cool oil lasts longer and works better than oil that has been continuously overheated. Therefore, the EGR system is important for the cool running of the engine and also in the protection of the engine oil from continuous heat.

In the real world, EGR valves often don’t work very well.

Exhaust gas recirculation is a nitrogen oxide (NOx) emissions reduction system used commonly in diesel engines. The EGR system works by recirculating a portion of the exhaust gas off the engine back to the engines cylinders. Modern engines require an EGR system to reduce the amount of emission and meet government standards.

Problems with the EGR valve often include a leaking or clogged valve. The problem causes pollution on the environment, and the vehicle to run poorly. Diagnosing the problem is simple with the right expertise, and repairs are just as simple.

Common Symptoms of a Bad EGR Valve

When an EGR valve goes bad, there are several symptoms to expect. The list of symptoms does not always occur together, and some do not show up until there are already severe problems. Anyone driving a vehicle with an EGR system needs to know what to look for when the system goes bad, including:

- Rough idling

- Really bad fuel kilometres

- Lack of power during acceleration

- Loss of power during idling

Check engine light is on with a trouble code The EGR valve becomes functional when the engine is under load and the engine coolant is at operating temperature. At startup and under light load conditions, the valve remains closed. As engine load and/or speed requirements and inputs from various temperature and pressure sensors change, the ECU calculates the appropriate analog “command” signal for the EGR valve. Valve position will change as the ECU varies the signal to regulate the amount of EGR allowed into the air intake manifold.

Common EGR Valve Faults

Vehicles with EGR systems often have diagnostic codes stored in the PCM memory. These codes display in the check engine light area on the dash, and alert drivers to an issue. The codes make diagnosing the problem easier to repair, and faster to catch.

| Code | Problem Area |

|---|---|

| P0401 | EGR system flow inefficient |

| P0403 | EGR solenoid circuit |

| P0404 | EGR system performance |

| P0405 | EGR pintle position circuit low voltage |

| P1404 | EGR valve stuck open |

| P1406 | EGR valve pintle position |

The diagnostic codes help point the driver in the right direction, but do not always offer up all the information needed for an accurate diagnosis. Not all vehicles have the codes stored in the PCM memory, so diagnosing the problem takes more knowledge of the system.

EGR Valve is Stuck Open

If the EGR valve is stuck in the open position, it creates a vacuum leak. This leak leads to inefficient combustion, which often causes rough idling and hesitation. Stalling sometimes occurs as a symptom when the valve is stuck open, but generally only in extreme cases. The vehicle needs atmospheric oxygen in order to combust carbon dioxide from the tailpipe. If the combustion chamber floods with exhaust due to an open EGR valve, certain functions suffer.

Diagnosing an Open EGR Valve

While the vehicle is idling in a parked position, check the plunger shaft to ensure it is not stuck open. An error code of P1404, or P1406 displays when the EGR valve is stuck open. Remove the valve and fill it with carbon cleaner. If fluid leaks out when turned upside down, it is sticking open. Use a valve cleaning kit and pull a vacuum on the valve.

EGR Valve is Stuck Closed

If the EGR valve is stuck closed, larger amounts of nitrogen, oxide emits from the vehicle. The vehicle may begin to knock. The spark knock occurs when the fuel mixture within the combustion chamber ignites before reaching the cylinder explosion. This results in disruption of engine timing.

Diagnosing a Closed EGR Valve:

While the vehicle revs up in the park position, have someone check to see if the EGR valve moves. When the EGR valve is stuck closed, an error code of P1406, or P0401 displays. The knocking sound is a dead giveaway that the EGR valve is stuck closed. Remove the valve and use a valve kit to clean out any debris.

Clogged EGR Valve

Chunks of carbon commonly block the EGR valves pintle from properly seating. The problem causes a rough idle and even stalling. This is because exhaust gas is not recirculating back into the engine at idle, and generally only happens when the vehicle exceeds 50 kph

Diagnosing a Clogged EGR Valve:

When carbon blocks the EGR valve an error code of P1404, or P1406 displays on the engine light area. Remove the valve. Use a valve cleaning kit to remove any debris that is clogging the passage. A multi-meter helps to diagnose a variety of valve issues, and saves time during the process.

Extended engine oil changes, incorrect or the quality engine oil, engine management, faulty EGR coolers, Catalytic Convertors and DPF’s all can contribute or be the most probable cause/reason for this type of clogged EGR valves

What causes the EGR and other components to clog up?

Ash in the DPF, which is a by-product of oil and fuel additives, is not removed by any regeneration process, then the whole system is suffering from similar build up carbon and combustion particulates.

Maintenance of the anti-pollution system involves periodical removal of the build-up of these ash deposits, this should be the only service necessary, as the OEM’s keep advising the customer.

When the estimated ash loading reaches a threshold, a DTC becomes active indicating for example; that the DPF requires a regeneration or cleaning within 5,000kms, although the engine management controls the regeneration process, there is a major problem if the problem is not rectified, the process continues and high fuel consumption is not the only problem the vehicle is going to affect the engines operation and performance.

When servicing or replacing the anti-pollution components, the qualified service centre, needs to perform a calibration, resting and/or setting the EGR position, the ECU needs to reset to the OEM to the parameters for the correct emission levels and operational conditions.

If these anti- pollution components are suffering from the Ash type build ups, most OEM’s and dealerships will only fit new components, rather than clean and rest those failed components.

Now we know they need regular cleaning, what’s next?

Linked to this problem, engine reconditioners have real problems trying to clean up the intake manifolds and the EGR valves and EGR coolers, many a time these components need two or three attempts in rotary washers.

At least the is a solution for this cleaning process, the ultra-sonic cleaning tanks have been one of the biggest improvement and more cost effective solution for the engine reconditioner.

Once the engine reconditioning process is complete and all the anti-pollution components such as the EGR and EGR cooler are clean and ready to go back to the workshop, advice is given that the DPF or similar types exhaust system should also been removed and cleaned, again the ultra-sonic tanks are the best option, and the engine management reset and calibrated.

Many workshops complain that the customer is reluctant to pay for this service, my answer is that the mechanic must be able to communicate this to his customer, if the engine had suffered an overheating problem, the components in the system would have replaced or serviced.

Ongoing care is required from then on, such as using the correct engine oil, servicing more regularly, using additives to keep the system clean and operating correctly.